Student Housing / Dormitory Heat Treatment Systems

Improve Student Experience

Don't wait for bed bugs to ruin your student experience! Traditional bed bug treatments can take weeks and will destroy your reputation in the interim. Join the hundreds of hospitality managers, property management companies and pest control professionals who have decided that self-treating with heat is the most effective and economical method of bed bug elimination available to student housing authorities. Kill bed bugs and their eggs with GreenTech Heat!

Why Self-Treat With GreenTech Heat?

Heat treatments kill 100% of bed bugs and their eggs in just one treatment.

Heat treatments kill 100% of bed bugs and their eggs in just one treatment. Immediate, in-house response to any infestation saves thousands on regular pest control company treatments.

Immediate, in-house response to any infestation saves thousands on regular pest control company treatments. See a return on your investment within three treatments.

See a return on your investment within three treatments. Treated rooms are only down for a few hours during treatment.

Treated rooms are only down for a few hours during treatment. No chemicals used with heat!

No chemicals used with heat!

Basic Guidelines To Bed Bug Heat Treatments

Every Living Organism Has A Thermal Death Point

The full details of heat treatments are provided in our “Heat Treatment Field Guide”. This is a basic approach to performing a heat treatment.

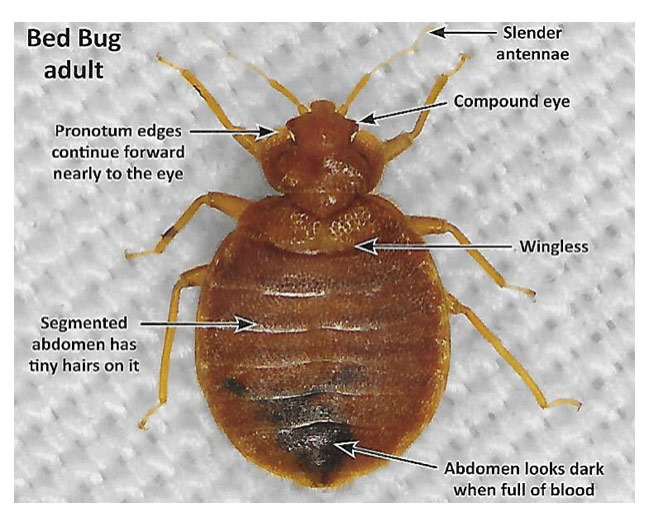

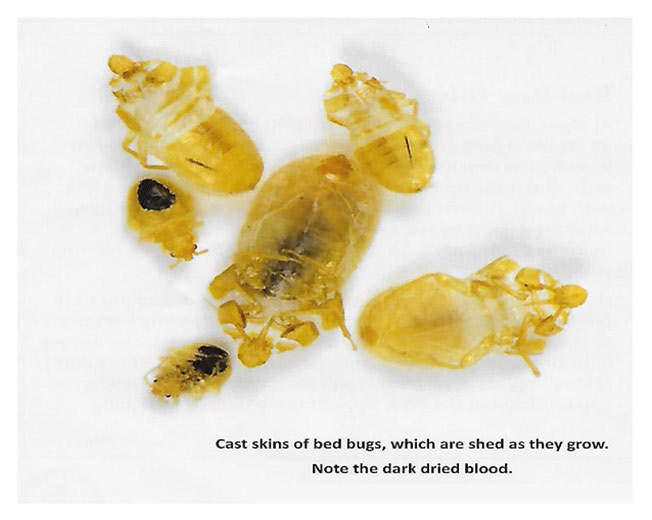

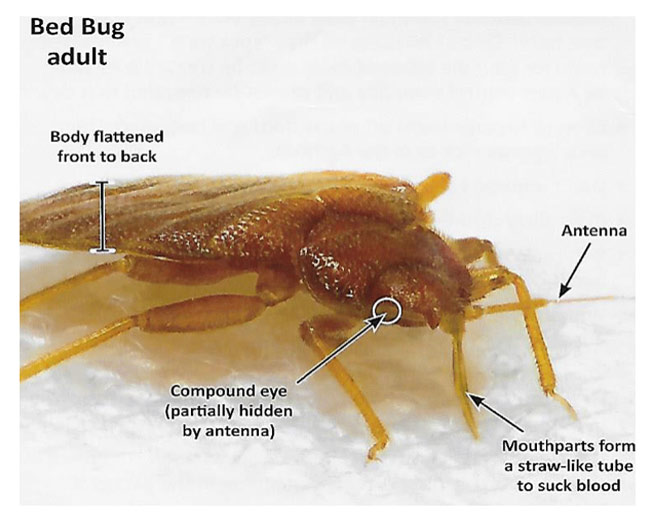

The same process for treating bed bugs will also kill, and in some cases, completely eradicate other organisms.

Regardless of the heat source, temperatures and run times must be achieved throughout the structure.

Let's Get Specific

Electric Vs Propane,

Heat systems affecting heat treatment run times and methodology.

- Electric heat is a closed system. It operates from within the structure being treated with heat. Electric heat is slower in the beginning of the heating process than propane.

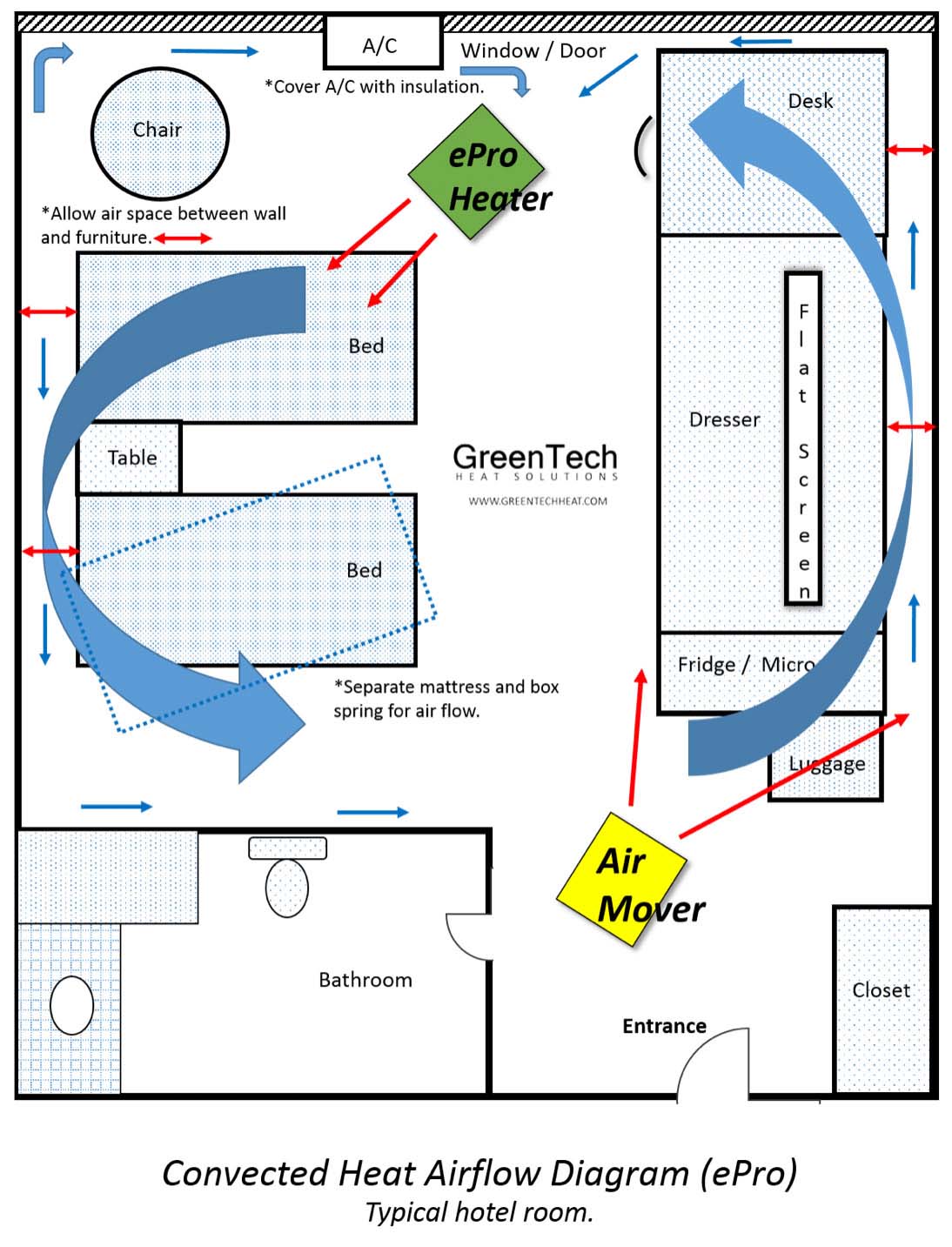

With ePro electric heat systems, starting room temperatures raise by approximately 10˚F or every hour. However, the ambient room air temperature will increase at a faster and faster rate as the room temperature rises and recycles itself. It is the multiplying effect of air turnover with a closed system.

Electric heat requires power sources. Adding more electric heaters, will be more productive to your heat treatments. However, the power source becomes a growing challenge. Each ePro electric heater is 120v and requires 45 amps to run at 100% power. GreenTech portable Power Stations are used to plug into 240v power sources like electric range and A/C and can provide more 120v power to the ePro heaters. Check your available amperes. - Propane heat is an open system. The unit stays outside the structure and the heat is ducted into the building. It produces positive air pressure. The units require a source of propane to operate.

Intense and immediate heating of the space. Higher air output, higher volume of heated air, high productivity capabilities as compared to electric systems. Propane can be divided with splitting the heat ducting to cover more area, rooms or even another unit.

Propane results in more thorough penetration and distribution of the heated air.

Typical Bed Room With Two Beds Or A Basic Hotel Room Set-Up

Heat Source Run Time Comparison

Equipment used: ePro electric 400 package

- Approximate square feet: 400

- Starting temperature: 75˚F

- Infestation: Moderate

- Target temperature: >130˚F +

- Estimated treatment time: 8 – 12 hours

Equipment used: Titan propane 3000 package

- Approximate square feet: 400

- Starting temperature: 75˚F

- Infestation: Moderate

- Target temperature: >150˚F +

- Estimated treatment time: 2 - 4 hours

Variables Do Apply

- Square feet: large or small space. The larger the area the longer heating time for all areas to reach lethal temperatures.

- Building materials: cement, steel, dry wall, etc. will affect the heating times. Cement floors and walls will take as much as 3 times the time due to the fact that cement acts as an insulator and can maintain cool temperatures with slowly changing thus requiring more heat time.

- Furnishings: lots of furniture will require more run time due to the amount of objects surface area needing to get to temperature and the obstacle of more furnishing for the heated air to travel through and around.

- Clutter: Piles of clothing and blankets are very important to move around and mix. The room air temperatures can be 130˚F and under the pile of clothing it could be 80˚F not lethal. No clutter, is recommended.

- Weather: heating in a desert or in high altitude with snow. Is it warm or hot when starting? Humidity and cold will take adjustments and more heat time.

- Degree of infestation: Identifying infestations early is key to control and is much easier to get a 100% kill. If the infestation is large and mature, basically way over due for treatment, you will need to take time to move objects, furniture, open all draws and closets and spend extra time prepping and allowing more time for longer heat penetration of the structure and furnishings.

- Starting temperature: Similar to weather but room temperature. Is the treatment beginning temperature at, for example: 90˚F or 40˚F?

All efforts should be taken to preheat a structure prior or during set-up of heat treatment equipment. Starting with a pre-heated room achieves faster arrival times for lethal temperature resulting in less treatment time, and higher productivity.

Please refer to our full listing “Compendium of Thermal Death Points” in our References tab under Technical support / support docs PDF. The death point data listed was taken from laboratory tests, not from field applications.